High-pressure laminate is a popular surface material because it combines excellent durability, versatile design possibilities and easy maintenance. The manufacturing process uses high pressure and heat, which makes the material more durable than conventional laminates. High pressure laminates are suitable for furniture manufacturing, interior design and architectural projects where both functionality and aesthetics are required.

What is high-pressure laminate and how does it differ from ordinary laminate?

High-pressure laminate is a composite material made by pressing together several layers of paper fibre under high pressure and temperature. The manufacturing process uses formaldehyde resins that bind the layers together to form a highly durable and compact material.

The main difference with ordinary laminates is manufacturing pressure and temperature. High-pressure laminates are manufactured at pressures of over 70 bar and temperatures of around 150 degrees Celsius, while ordinary laminates are manufactured at lower pressures. This makes high-pressure laminates significantly harder, denser and more durable.

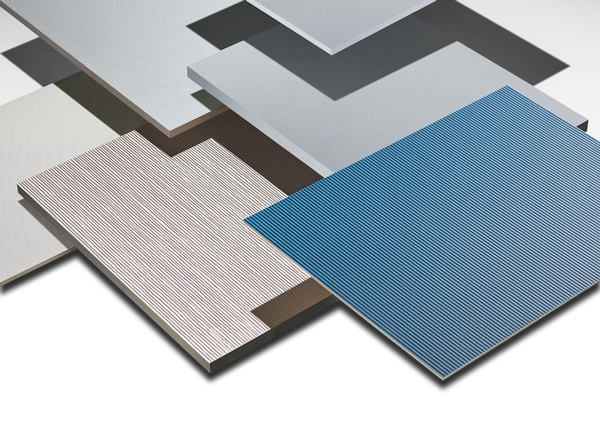

Structurally, high pressure laminate consists of several layers: a base paper, a colour layer and a protective top layer. The top layer can be glossy, matt or textured, allowing for a wide range of design solutions. The thickness of the material typically varies between 0.6 and 1.5 mm.

Why do designers and manufacturers choose high pressure laminate over other materials?

The popularity of high pressure laminate is based on its superior durability and design versatility. The material resists scratches, impact and heat better than many other surface materials. It is also moisture resistant and hygienic, making it ideal for public spaces and kitchens.

From a design point of view, high pressure laminate offers almost limitless possibilities. There are hundreds of different colours, patterns and textures available. The material can mimic natural materials such as wood or stone, or it can be a completely abstract design pattern. This versatility makes it a popular choice for architects and interior designers alike.

Practicality is another major advantage. High-pressure laminate is easy to work with, requires no special tools and can be bonded to a wide range of substrates. The material is also cost-effective compared to many other premium surface materials, making it an attractive choice for a variety of projects.

What can high pressure laminate be used for in interior design and construction?

High pressure laminate is suitable for versatile for different applications in interior design and construction. The most common application is in kitchen and bathroom worktops, where moisture resistance and hygiene are important properties.

In furniture manufacturing, high pressure laminate is used for cabinet doors, drawer fronts and desk tops. The material is resistant to daily wear and tear and retains its appearance for years. In public spaces such as offices, schools and hospitals, high pressure laminate is a popular choice for its durability and ease of cleaning.

For wall surfaces, high-pressure laminate works well, especially in damp areas and areas subject to heavy wear and tear. It is also used as a coating for furniture and interior panels to create attractive and durable surfaces. In architectural applications, the material is used for interior facades and special structures.

How long does high-pressure laminate last and how do you maintain it?

High pressure laminate is very durable material, which will last for decades under normal use. A properly installed and maintained high pressure laminate will retain its appearance and performance for 15-25 years or even longer depending on the conditions of use.

Maintenance of the material is simple and easy. Daily cleaning can be done with a damp cloth and mild detergent. More difficult stains can be removed with alcohol-based cleaners or specialised laminate cleaners. However, avoid abrasive cleaners and steel wool, which can damage the surface.

During use, avoid direct contact of hot objects with the surface and use cutting boards when working with sharp objects. Although high-pressure laminate is durable, proper handling will extend its life even further. Small scratches can often be sanded away with fine sandpaper and the surface polished back to its original condition.

Contact our experts to support your material choices

The selection of high-pressure laminates for a project often requires expertise in the technical properties of the materials and their suitability for different applications. Each project is unique and finding the right material requires a thorough understanding of both the application and the aesthetic requirements.

We have years of experience working with high quality surface materials. We can help you find the right high-pressure laminates for your project, meeting both functional and aesthetic requirements. Contact us for personalised advice on material selection.

We offer comprehensive support from the planning phase to implementation. You can discuss the technical properties of materials with our experts, get samples to evaluate your project and get tips on how to make the best use of materials. We make material selection easier and ensure that your project is the best possible success.