Laminate is one of the carpentry industry's key surface materials, combining aesthetics and technical properties in a unique way. The main technical properties of laminates used in the joinery industry relate to wear and impact resistance, moisture resistance, thermal properties, surface texture and workability. These properties determine the suitability of the material for different applications and have a significant impact on the quality, lifetime and appearance of the final product. Choosing the right type of laminate always requires a project-specific assessment of the technical characteristics.

The role of laminate in the modern joinery industry

Laminate is well established as a versatile surface material in the modern carpentry industry. Its popularity is based on its excellent price-performance ratio and a wide range of technical features that make it suitable for numerous applications.

In the carpentry industry, laminate is used in particular for furniture, worktops, office furniture, kitchen furniture and various structural surfaces. High-pressure laminate is the material of choice for professionals because it combines durability, malleability and visual versatility.

Understanding the technical properties of laminates is important for carpenters and joiners, as it helps to select the optimal material for each application. The physical and chemical properties of the material determine how well it will withstand daily use, wear, moisture and heat.

What are the main durability characteristics of laminate?

The main durability properties of laminate are wear resistance, impact resistance and scratch resistance. These properties determine the material's lifetime and suitability for different types of applications in the carpentry industry.

Wear resistance is commonly measured by the Taber test, where the surface of the laminate is sanded with a specified number of rounds of abrasive paper and the surface wear is measured. High quality laminates can withstand more than 400 cycles without significant wear. This property is particularly important in applications where the surface is subjected to constant mechanical stress, such as worktops.

Impact resistance is the ability of a material to absorb the energy of a sudden impact without cracking or splitting. In the carpentry industry, this property is particularly important for public furniture and surfaces that are exposed to heavy use. High pressure laminates are typically more impact resistant than lower pressure laminates.

Scratch resistance is an important property for maintaining appearance. It is usually measured by the Mohs scale or by special tests in which the surface is scratched with materials of different hardness. A high quality laminate will effectively resist scratching and retain its visual appearance for a long time.

How does the moisture resistance of a laminate affect its applications?

The moisture resistance of a laminate is a key property that directly affects its suitability for different environments. High pressure laminates (HPL) are naturally moisture repellent, making them an excellent choice for damp areas such as kitchens and humid working environments.

Moisture resistance is usually measured by a moisture absorption test, where the laminate is immersed in water for a specified period of time and the change in weight of the material is measured. High quality laminates absorb very little moisture (typically less than 1% by weight), which prevents swelling and deformation of the material.

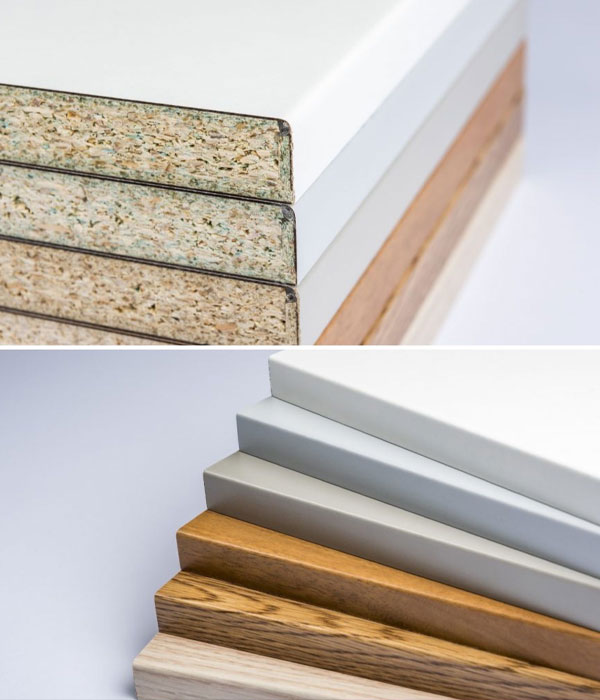

There are significant differences in moisture resistance between different types of laminate. Compact laminates, which are the same material throughout, offer excellent moisture protection. In contrast, ordinary thinner laminates require more careful installation and edge protection against moisture.

Moisture resistance is particularly important in laboratory furniture, healthcare facilities and kitchens where surfaces come into regular contact with liquids. Consideration of water vapour permeability and swelling will help to select the right type of laminate for each application.

What thermal properties make laminate suitable for different applications?

The thermal properties of a laminate are an important determinant of its suitability for different applications. Heat resistance is particularly important in the joinery industry when laminate is used, for example, on kitchen worktops or near heat sources.

High-quality high-pressure laminates typically have a heat resistance of 160-180°C, which allows them to withstand short-term exposure to hot objects such as pans or pans. However, prolonged exposure to high temperatures can cause discolouration, cracking or material degradation.

Fire resistance properties are particularly important for laminates used in public spaces. In Europe, the fire classification of laminates follows the EN 13501 standard, with classes ranging from A1 (non-combustible) to F (highly flammable). In the carpentry industry, B-s1,d0 or B-s2,d0 rated laminates are often used, which offer good fire safety.

Thermal expansion is also a property to consider, especially on large surfaces. The coefficient of thermal expansion of laminate is typically quite low, making it a stable material at varying temperatures. This property is an advantage, for example, for surfaces close to heat sources.

How does the surface structure of a laminate affect its technical properties?

The surface texture of a laminate is not only an aesthetic factor, but also has a significant impact on the technical properties of the material. Surface pattern and texture contribute to the wear resistance, cleanability and appearance of the laminate.

Smooth-surface laminates are easy to clean and hygienic, which is why they are particularly popular in healthcare facilities and laboratories. On the other hand, textured, patterned surfaces better hide scratches and wear, extending the aesthetic life of the material in high-wear environments.

Matt laminates reflect less light and are more fingerprint resistant, but can be more prone to staining than glossy surfaces. Glossy surfaces, on the other hand, enhance the lightness of a space but show scratches and wear more clearly.

The choice of surface structure also affects the anti-static and anti-bacterial properties. Some special laminates have antibacterial coatings that make them ideal for hygiene-critical applications. These properties are particularly important for hospital and food service furniture.

How can laminate be processed in the joinery industry?

Laminate is a versatile material, which makes it a popular choice for the joinery industry. Its machining characteristics have a significant impact on the efficiency of the installation and the quality of the final result.

Laminate can be cut using a variety of methods, such as panel saws, CNC milling cutters or hand tools. For cutting high-pressure laminates, the use of carbide blades is recommended, which are resistant to wear and ensure a clean cut. The use of sharp tools prevents chipping and cracking of the edges of the laminate.

Milling allows complex shapes and edge profiling. CNC milling has become popular in the joinery industry because it offers precision and repeatability. In laminate milling, the optimum rotation speed and machining speed depend on the thickness and grade of the laminate.

Gluing the laminate to the substrate is a critical step in the installation process. Recommended adhesives include contact adhesives and PVAc-based adhesives, which provide a strong bond. Optimising the bonding temperature and pressure is important to avoid cracks and bubbles.

KERROCK composite panels are also an excellent option for the carpentry industry. Kerrock material has the machinability of hardwood, but offers better moisture resistance and mouldability. It can be thermoformed into different shapes and seamlessly joined, allowing for versatile design solutions.

Exploiting the technical properties of laminate in projects

Understanding the technical properties of laminate is key to successful projects. For each application you need to choose suitable characteristics a laminate solution that meets the technical and visual requirements of the project.

For demanding applications, such as laboratories or public spaces, it is advisable to choose chemically resistant and high wear laminates. For kitchen furniture, the emphasis is on moisture and heat resistance and hygiene. For high-impact interior design, visual characteristics and workability are a priority.

It is important to consider the whole life cycle of a material, from design to installation and maintenance. Careful design and the right working methods ensure that the technical properties of the laminate are fully exploited and that it has a long service life.

We offer a wide range of high quality laminates, such as ABET LAMINATI high pressure laminates, suitable for the most demanding carpentry projects. KERROCK composite panels, on the other hand, bring to our range a versatile material that combines the durability and formability of laminate. Our experts will help you choose the most suitable materials for each project, meeting both technical and aesthetic requirements.